In the rapidly evolving world of architectural design and construction, technology plays a pivotal role in transforming traditional methodologies into highly efficient, precise, and scalable solutions. This case study delves into how Indiecad, a leader in surveying and reality capture technologies, leveraged state-of-the-art laser scanning and 3D modeling to redefine warehouse renovation projects. By embracing innovation, Indiecad not only addressed common industry challenges but also set new benchmarks for accuracy and efficiency in commercial refurbishments.

Technology and the Creation of Digital Twins

Transforming a Commercial Warehouse

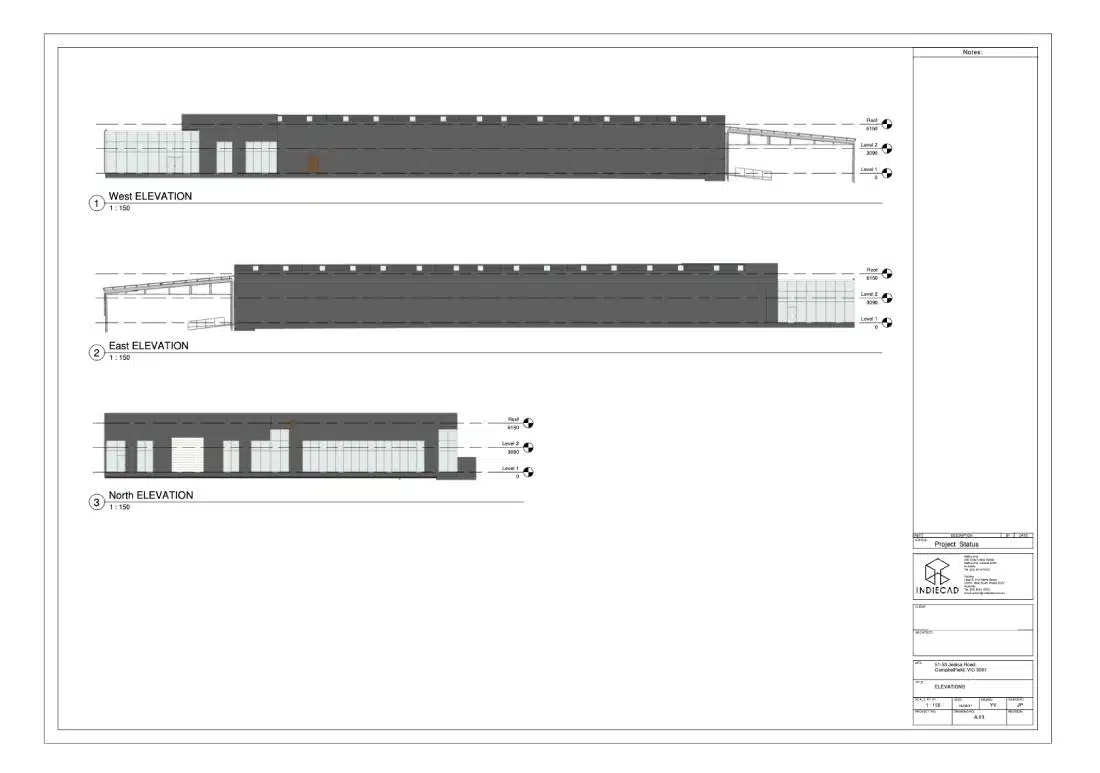

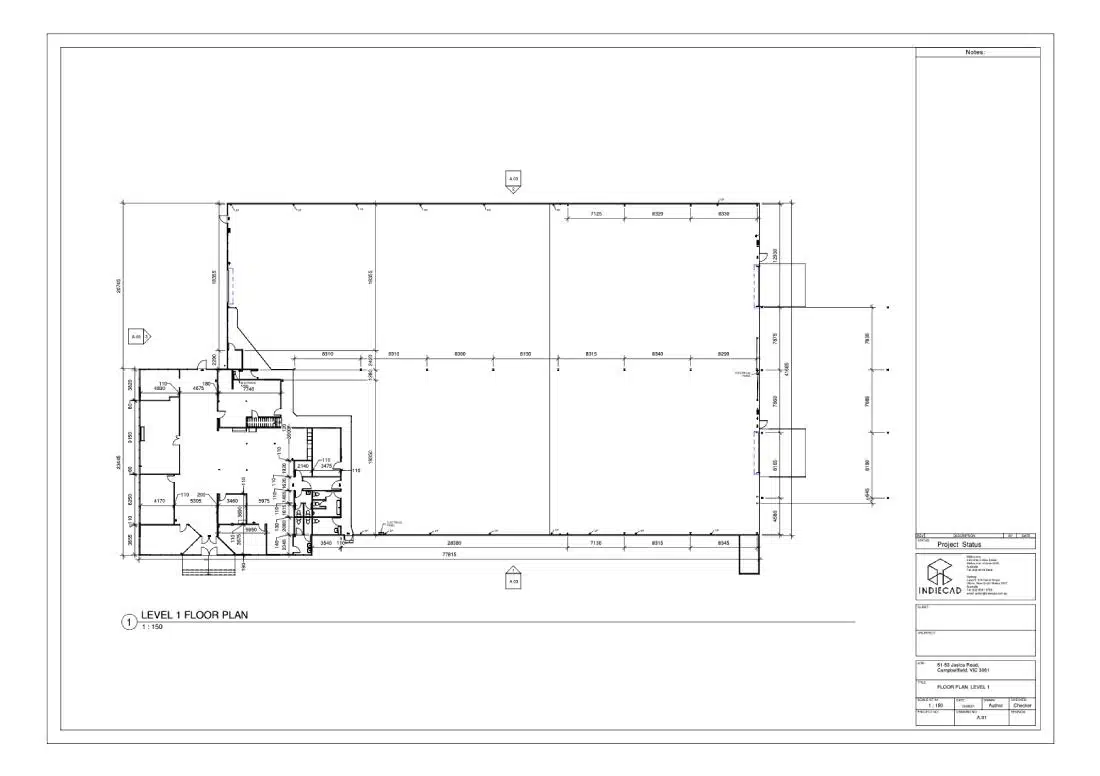

Indiecad was approached by a commercial property owner faced with the daunting task of renovating an outdated warehouse. The primary challenge was the absence of accurate and up-to-date as-built drawings, a common hurdle that often leads to project delays, increased costs, and compromised design integrity. Indiecad proposed a comprehensive solution employing laser scanning and 3D modeling technologies to overcome these challenges and ensure a smooth, efficient renovation process.

Indiecad’s Innovative Approach

Initial Assessment and Planning

The first step in Indiecad’s process was conducting an initial site assessment to understand the warehouse’s current condition and the project’s scope. This phase involved preliminary discussions with the client to align on objectives, timelines, and specific requirements for the renovation.

Laser Scanning and Data Capture

Utilizing a high-precision Leica laser scanner and a DJI RTK drone, Indiecad’s team performed a detailed scan of the entire warehouse, including its interior, exterior, and rooftop installations. The laser scanner captured millions of data points, creating a dense point cloud that accurately represented the warehouse’s physical characteristics.

3D Modeling and Digital Twin Creation

The collected data was then processed to generate a comprehensive 3D model of the warehouse in Revit, effectively creating a digital twin of the structure. This model served as a foundational tool for planning the renovation, allowing the design team to explore various design scenarios, conduct structural analyses, and plan construction phases with unprecedented precision.

Collaboration and Implementation

The digital twin was shared with all stakeholders, including architects, engineers, and the construction team, fostering a collaborative environment. The ability to visualize the entire warehouse in 3D streamlined the decision-making process, enabled efficient communication, and facilitated the identification and resolution of potential issues before construction began.